Future-oriented manufacturing processes in focus

15th May 2023

The CHIRON Group OPEN HOUSE impresses trade visitors

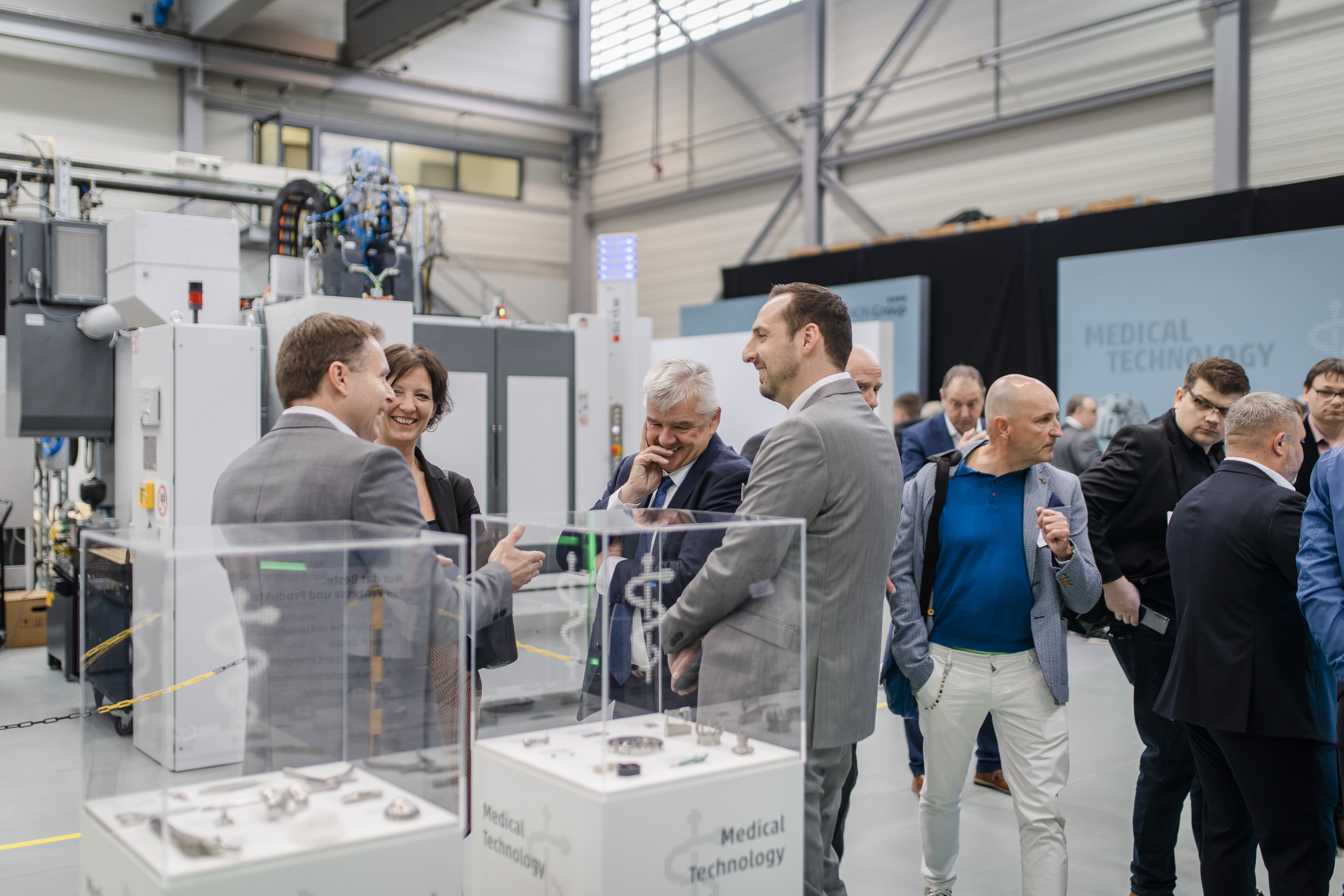

From May 10 to 12 it was OPEN HOUSE time again in Tuttlingen, Germany. And this year too, the event lived up to its reputation as a driving force and communication platform for the entire industry.

Over three days more than 1,300 exhibition visitors were able to follow live examples of machining operations that demonstrate how the CHIRON Group transfers the specifications of the various user industries into future-oriented production processes. Example for Automotive: the unit cost-optimized machining of e-motor housings with the new addition to the 22 Series, the DZ 22 S mill turn system 8 milling and turning center. Illustrative for demanding machining in Medical Technology: the production of a dental workpiece in reproducible quality with the compact, highly efficient Micro5 5-axis center.

In addition, the guests were able to get to know the different areas of expertise of the CHIRON Group, experience the first high-speed spindle from its own production in action or get advice on comprehensive automation solutions that also include follow-up processes in addition to autonomous machining.

As part of the partner exhibition, 26 companies provided information about their products and solutions. The spectrum ranged from cutting tools and clamping technology to lubricants and the automation of tool processes. The technology partners particularly appreciated the networking opportunities that the OPEN HOUSE offered them. The lectures on the "competent & smart" and "innovative & sustainable" topic days were also well attended, for example on the new leasing model of the CHIRON Group with a smart combination of financing and full service.

The highlight for everyone was the "Get together" on the second day, accompanied by the relaxed, predominantly Bavarian music by Dis M. A personal highlight from CSO Bernd Hilgarth was "The intensive, productive exchange with our guests and the positive feedback on our expanded range of services with which we position ourselves as a partner for the future."

About the CHIRON Group

The CHIRON Group, headquartered in Tuttlingen, Germany is a global company specializing in CNC vertical milling and mill-turn machining centers, as well as turnkey and automation solutions. Comprehensive services, digital solutions and products for additive manufacturing complete the portfolio. The Group has a global presence, with production and development sites, sales and service subsidiaries, and sales agencies worldwide. Around two thirds of machines and solutions that are sold are exported. Key customer sectors are the automotive, mechanical engineering, medicine and precision engineering, aerospace industries, as well as tool manufacturing.

The CHIRON Group is proprietor of the CHIRON, STAMA and FACTORY5 brands for new machines, as well as the automation brand GREIDENWEIS, CMS for refurbishment and HSTEC for motor spindles and fixtures. CHIRON machining centers are renowned for their highly dynamic design and their precision. The focus of STAMA is on stability and complete machining, while FACTORY5 expert area is high-speed machining of micro-technical components. GREIDENWEIS is a system partner for custom, end-to-end automation solutions, and CMS provides completely refurbished machines from the Group. HSTEC specializes in the development, manufacture and repair of high-speed motor spindles and fixtures. The final core area of expertise in the CHIRON Group is in additive manufacturing products and solutions.

Contact person for editors:

CHIRON Group SE

Christina Messmer

Kreuzstraße 75, 78532 Tuttlingen, Germany

Phone: +49 7461 940-3712

Mail: [email protected]